TEAM Technologies

Is Helping Those Who Help Others to Solve the Healthcare Industries' Most Complex Challenges

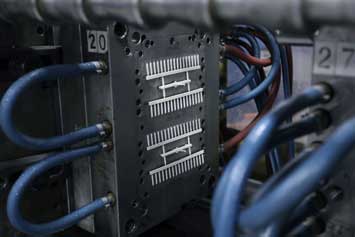

READ MOREDiagnostic IVD Testing

Benefit from our Decades of Experience and Advanced Technologies to Positively Impact the Lives of Others with Innovative Diagnostic IVD Tests

READ MOREPatient Monitoring

We Develop Wearable Sensors for Patient Monitoring Applications Leveraging our U.S.-based Manufacturing and Supply Chain Capabilities

READ MOREWound Care

Our Products are Developed with the Newest Technologies and Processes that Support Advances in Wound Care Techniques and Treatments

READ MOREInfection Control Products

Our Infection Control Products are Simple, Convenient and Adaptable To Help Protect Patients, Caregivers and Those That Work The Frontline of Clinical and Industrial Settings

READ MOREPharmaceutical Delivery Devices

We Manufacture Pharmaceutical Delivery Devices and Dosing Systems Built to be Accurate and Precise, Ultimately Improving the Patient Experience

READ MOREOral Healthcare

From Concept to Commercialization, We Offer the Technology and Support for Every Stage of the Development and Manufacturing of Oral Healthcare Devices

READ MORECompression Devices

We Partner With You to Develop Unique and Cutting-Edge Solutions that Help Protect and Save Lives.

READ MOREPatient Handling

We Partner With You to Develop Quality Products that Protect the Patient and Caregiver.

READ MORE